Long gone are the early whacking days in Scotland. Back in the 15th century they hardly thought of how much the golf ball technology will evolve. The earliest ones were made from wood. It is hard to imagine smacking a wooden ball off the tee, right? How golf ball technology has changed over the decades is simply fascinating.

After the wooden ball came the ‘featherie’, a leather pouch stuffed with goose feathers. Then, in the mid-19th century, the gutta-percha ball arrived. Made from the sap of the Malaysian sapodilla tree, these balls were cheaper and more durable than featheries. That led us into the 20th century where balata and wound golf balls appeared. Finally, technology brought us modern-day multi-layered balls. Let’s embark on the golf ball technology journey.

The Early Days: Featheries and Gutta-Percha Balls

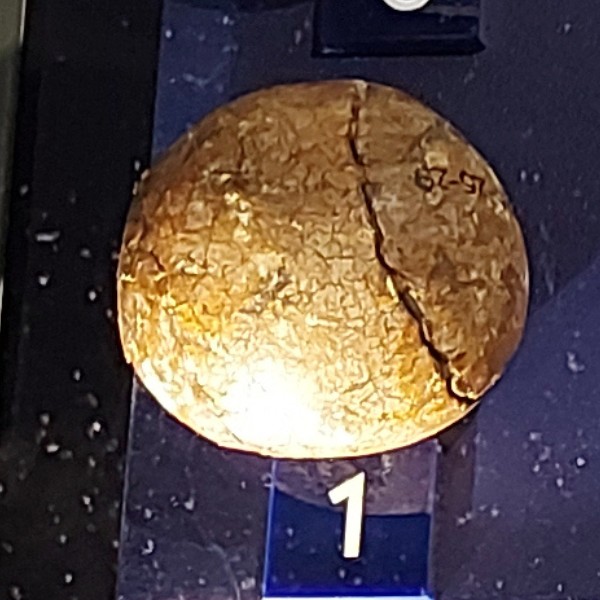

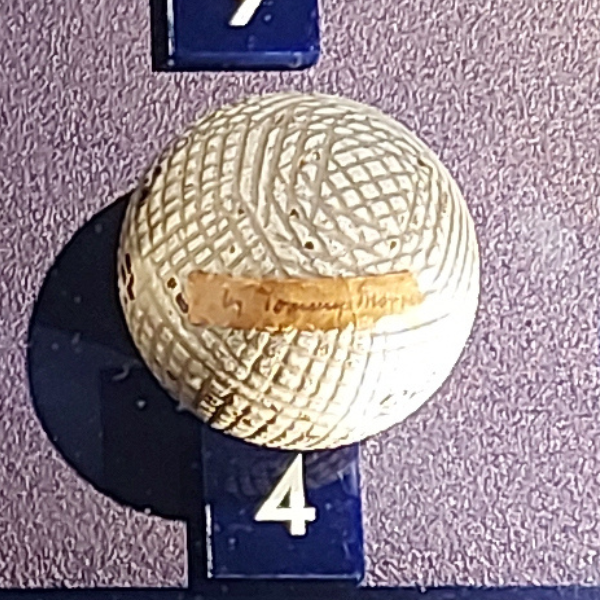

Crafted with a leather pouch tightly packed with goose feathers, these balls were handmade and took considerable time and effort to produce. This demanding process made them pricey and limited to the more affluent players. Featheries were known for their relatively short lifespan and frequent need for repairs. However, they represented a significant step forward from the earlier wooden balls.

Everything changed in the mid-19th century with the introduction of the gutta-percha ball. Created from the sap of the Malaysian sapodilla tree, these golf balls were a game-changer. They were cheaper and more durable than featheries, and more importantly, could be mass-produced. This led to a new era where golf became more accessible to a broader audience.

Gutta-percha balls provided improved performance, offering a harder surface that could better withstand the impact of clubs. Their rigidity allowed for a more consistent flight path and better control, improving the overall gameplay. The shift from featheries to gutta-percha balls marked one of the first significant technological advancements in golf ball design. It laid the foundation for future innovations.

The 20th Century: Balata and Wound Golf Balls

The introduction of balata covers at the beginning of the 20th century meant another technological leap. Balata, a natural rubber-like material, provided excellent control and spin. The soft feel of Balata-covered balls appealed to those seeking precision and finesse in their game.

However, the Balata balls were prone to cuts and damage, especially when hit poorly or on harder surfaces. But if you could keep them in good shape, the level of control and spin was unmatched. It made these balls ideal for those who prioritized short-game performance over durability.

The invention of wound golf balls was another pivotal moment. These balls featured a solid or liquid core wrapped in a rubber thread layer and then encased in a Balata cover. This design offered a balance of distance and control. They were the go-to choice for many golfers for several decades.

The winding process allowed for a more uniform energy transfer, which meant more consistent shots. This precision gave golfers confidence in their equipment. Knowing how the ball would respond with each shot was an important part of the game. Balata covers and wound construction represented the pinnacle of golf technology for much of the 20th century.

Moderna Era: Multi-Layered Golf Balls

By the late 1990s and early 2000s, golf technology was reaching new heights. The introduction of multi-layer golf balls revolutionized the game, combining different materials to optimize performance. This era introduced three-pieced, four-piece, and even five-piece designs. Each layer was engineered to enhance a specific aspect of the ball’s flight and feel.

These multi-layer balls typically feature a solid or liquid core, surrounded by multiple layers of synthetic materials. The core is designed to produce maximum distance while the outer layers improve control and spin.

Professional golfers quickly embraced the benefits. Players like Tiger Woods, who began using these advanced multi-layer balls, saw significant improvements in their games. Even the most advanced players could fine-tune their shots more than ever before.

Their versatility was one of the multi-layer golf balls’ key advantages. Whether you are looking for extra yardage or short-game control, there is a multi-layer ball that fits your style. The different layers work together to meet the demands of various shots. Additionally, they offer a balanced performance that can adapt to the needs of any golfer.

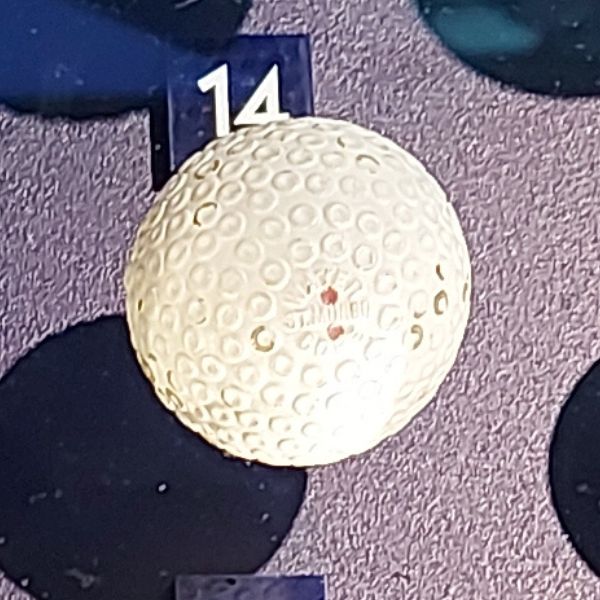

These balls also feature high-tech coatings and innovative dimple patterns that enhance aerodynamics. This means they cut through the air more efficiently and provide better stability in various weather conditions. The modern multi-layer golf ball can offer a level of performance that was once unattainable.

Technological Innovations: Aerodynamics and Spin Control

Golf ball technology is heavily influenced by aerodynamics and spin control. One of the most noticeable features of a modern golf ball is its dimple pattern. These dimples are carefully designed to manage airflow, helping the ball travel further and more accurately.

Engineers test thousands of patterns to find the optimal configuration that reduces drag and increases lift. It can significantly impact your game. The right dimple design can make the difference between landing on the fairway or ending in the rough (or worse).

Materials used for the ball’s cover and core are another technological marvel. Advanced polymers and nanomaterials have revolutionized how the ball behaves upon impact. These high-tech materials offer enhanced durability and control, letting you get more out of each swing.

Spin control is another critical area. Multi-layer constructions allow for precise spin rates, which is crucial for short-game control. Higher spin rates can help with stopping power on the green. On the other hand, lower spin rates are better suited for longer, more accurate drives. Knowing how your ball spins gives you an edge, especially when dealing with challenging conditions like wind or rain.

Engineers use high-speed cameras and software to analyze every aspect of the ball’s flight. This way they ensure it performs exactly as intended. This data-driven approach allows for continuous refinement and improvement.

The Future of Golf Ball Technology

Innovations in materials and manufacturing processes promise to push performance boundaries even further. Even with the announced golf ball rollback, there will be technological improvements. One of the most exciting areas is the development of sustainable and eco-friendly materials. Golf companies are increasingly aware of their environmental impact. Therefore, new materials that are both high-performing and biodegradable are on the horizon.

Another hot topic is the integration of smart technology. Picture a golf ball embedded with tiny sensors that provide real-time data on each shot. This tech could offer insights into swing speed, spin rate, and even the exact location of your ball.

Looking forward, expect to see more collaborative efforts between scientists, engineers, and golfers. The best innovations often come from a blend of practical knowledge and technical expertise. So, don’t be surprised if you soon start hearing about golf balls designed by AI or based on aerospace engineering principles.

Exciting times are ahead as the next generation of golf balls promises to make the game more enjoyable than ever.

Related

- How Are Modern Golf Balls Made – The Technology Behind

- What Is Golf Ball Compression?

- What Is the Shelf Life of a Golf Ball?